Quick Tool for Material Compatibility: https://www.trelleborg.com/apps/mc/

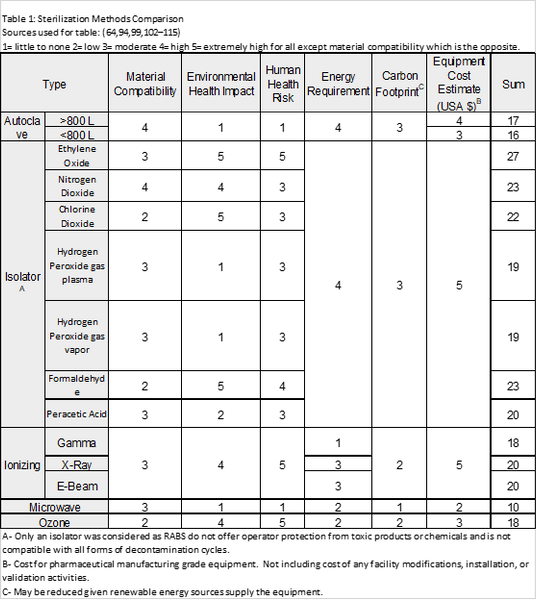

There are several factors that must be considered when selecting the optimal sterilization method for a given product and process. The cost of the equipment, material compatibility, energy demands, carbon footprint, and both human and environmental health impacts should be considered. Additional considerations could also be considered like sterilization time, load size, and where the energy for the equipment is coming from, which could offset both the carbon, energy, and water demands. For the purpose of this analysis, the first set of considerations were examined and judged on a scale of 1-5 with all methods having 1= little to no impact or cost, 2= low impact or cost, 3= moderate impact or cost, 4= high impact or cost, 5 = extremely high impact or cost. With this scaling, the sterilization methods can be easily compared against each other. For example, in Table 1 below, Autoclave has a 4 for material compatibility because this modality is compatible with both liquids and solids that are not heat sensitive (cause degradation to media or to material). The environmental health impact with a score of 1, is the energy and water demand and does not create any toxic by-products or greenhouse gasses. The human health risk is for the autoclave equipment operators, scored as a 1, and is for the risk of burns when loading, unloading, or performing maintenance on the equipment. The burn risk(s) can be mitigated by requiring PPE and having automation settings that do not allow the chamber to be opened until a set temperature is reached. The energy requirement of a 4 was set due to the energy demands of supplying steam to the autoclave jacket and chamber as well as the energy to pull a vacuum and pressurize the vessel during a cycle. The carbon footprint score of a 3 is due to the larger energy demands for clean steam. This demand and score could be lower if the water is recycled and if the energy to supply steam and electricity is supplied from a renewable source like wind, solar, or another modality that would need to be considered on a case-by-case basis. The equipment costs will vary and were only considered for GMP pharmaceutical grade manufacturing equipment. This requirement increases the costs for the equipment across the board due to the strict processing requirements, as well as data integrity, which is leading the industry towards digital batch records, live recorded readings for all automated processes like temperature and pressure at a given time, as well as individual logins for users. With these requirements in mind, a small autoclave <800 L cost is in the hundreds of thousands, and for a large autoclave >800 L can easily be over a million dollars which is why the rating of 3 and 4 were assigned respectively.

Microwave technology has the lowest rating and therefore is the best method, assuming the material is compatible, for sterilization. Microwave sterilization technology is readily used in the food processing energy but is not yet used broadly in the pharmaceutical manufacturing field. While the technology can meet the sterilization requirements set by regulatory agencies, it has not been considered for the industry until the recent decades. Autoclaves, utilizing steam heat, are the second-best modality and have been widely used in the pharmaceutical industry for decades. There is opportunity depending on the age of the autoclave to change the setting so that it idles and does not supply steam to heat the jacket between loads. This would reduce the energy and carbon footprint between runs and benefit both the business and the local energy grid. For future installation projects consideration should be given towards implementing the best sterilization method that is compatible with the product(s) and integrating clean energy supplies from renewable sources.

North Carolina is ranked as one of the top five states for biotechnology industries and it is continuing to grow. North Carolina has been working to change the energy landscape by collaborating with public and private sectors to reduce greenhouse gas emission statewide, develop a clean energy plan, and incentivize new technologies. The state’s clean energy plans goals are clear and expected to drive the state to being carbon neutral by 2050. By collaborating with the biotech industry and incentivizing clean energy through optimizing processes within facilities this could be a major win for North Carolina’s clean energy plan. The ratings in the table are totaled and the lower the rate the more desirable the modality given its health impacts and business value.